Key Takeaways

- Artificial Intelligence (AI) is becoming integral to predictive maintenance and quality control.

- The Industrial Internet of Things (IIoT) enhances real-time data collection and analysis.

- Digital twins enable virtual simulations for improved decision-making.

- Sustainability practices are increasingly prioritized in manufacturing processes.

- Cybersecurity measures are crucial for protecting interconnected systems.

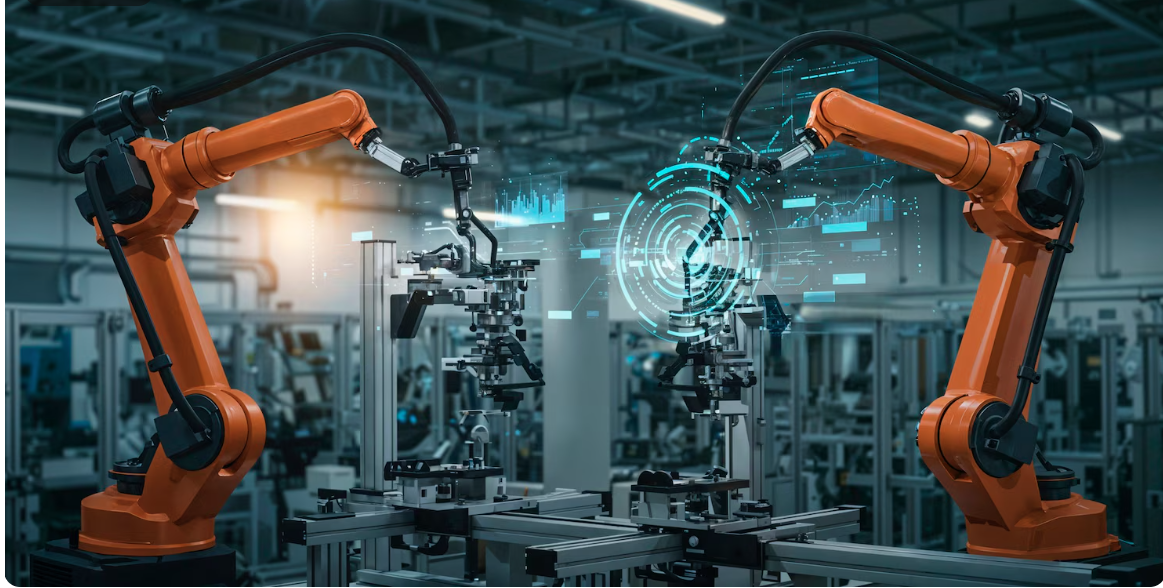

In 2025, the manufacturing industry is undergoing a seismic transformation driven by rapid technological adaptation and heightened market demands. Modern manufacturers know that staying on the cutting edge isn’t a luxury—it’s an absolute necessity. From leveraging powerful predictive analytics to deploying innovative connected devices, embracing new advancements isn’t just about maximizing output; it’s about driving growth and innovation. It’s about future-proofing your enterprise, boosting operational resilience, and securing a competitive edge. Within this context, businesses across sectors, from electronics to turbine tool sales and rentals are investing in breakthrough technologies that streamline workflows and deliver measurable sustainability gains.

As interconnected supply chains and global competition intensify, manufacturers willing to adapt reap benefits ranging from enhanced product quality to reduced downtime. Whether you’re planning to overhaul your production line or seeking ways to minimize energy waste, staying ahead of technological trends remains crucial. The following guide decodes the smart manufacturing trends projected to shape the industry by 2025, providing actionable insights for leaders and stakeholders.

AI Integration in Manufacturing

Artificial Intelligence (AI) is transitioning from a frontier innovation to a mainstay of manufacturing operations. By 2025, an overwhelming majority of manufacturers (95%) will be actively investing in or planning to integrate AI/ML solutions, ranging from predictive maintenance to advanced quality assurance. Smart manufacturing harnesses data from connected devices and sensors to anticipate equipment failures, optimize repair schedules, and streamline quality inspections.

This shift results in less downtime and higher consistency in finished products. AI-driven vision systems spot defects with greater accuracy than manual inspection, while machine learning algorithms optimize supply chain logistics and production scheduling. The adoption of AI doesn’t just raise productivity—it also empowers organizations to pivot faster in response to market demands, securing a distinct advantage over slower-moving competitors.

Expansion of IIoT

The Industrial Internet of Things (IIoT) is revolutionizing the way factories operate. As hardware, machines, and workers become part of an intelligent ecosystem, manufacturers benefit from real-time decision-making based on up-to-the-minute data streams. By 2026, with the maturation of 5G networks, factories will move toward a fully interconnected environment.

This always-on connectivity delivers substantial operational value, including remote equipment monitoring, automated inventory updates, and instant alerts for preventive action. IIoT implementations result in faster response times and more resilient processes—a crucial advantage for sectors that rely on precision manufacturing.

Adoption of Digital Twins

One of the most exciting trends in smart manufacturing is the adoption of digital twins. These virtual replicas of physical assets, such as production lines, products, or entire facilities, enable the accurate simulation of real-world scenarios. Manufacturers use digital twins to trial design optimizations, revise assembly sequences, and even predict supply chain disruptions, all without interrupting day-to-day operations.

With digital twin technology, businesses can quickly iterate on new concepts, reduce product development cycles, and lower costs—results that are already visible at scale in industries such as automotive and aerospace. The ability to test in a risk-free digital environment leads to smarter decisions and continuous improvement over time.

Emphasis on Sustainability

Societal pressure, evolving regulations, and energy constraints are making sustainability a pivotal element in manufacturing strategy. Companies, both large and small, are prioritizing eco-conscious practices—driven not only by regulatory compliance but also by customer expectations and investor demands. Manufacturing leaders are deploying energy-efficient equipment, reengineering processes to minimize waste, and sourcing materials with lower environmental footprints.

The payoffs from green manufacturing range from cost savings and risk reduction to improved brand loyalty. Practices such as circular supply chains and renewable integration are now fundamental building blocks for future-ready production, ensuring profitability, agility, and a positive environmental impact.

Enhanced Cybersecurity Measures

As technology reshapes manufacturing, the threat landscape expands in tandem. The modern factory floor now teems with smart sensors, autonomous vehicles, and cloud-connected controls—each a potential entry point for cyber attackers. In fact, manufacturing was the single most targeted industry for ransomware in recent years, with incidents highlighting costly disruptions and data breaches.

To counteract these threats, forward-thinking organizations are investing heavily in cybersecurity: deploying AI-based threat detection systems, regularly training staff on best practices, and seeking new hires with tech-driven security expertise. Robust cyber readiness isn’t just an IT concern—it’s now fundamentally intertwined with overall operational resilience and business continuity.

Anticipating, adopting, and scaling these trends will empower manufacturers to drive continuous improvement and sustained success in the face of ongoing disruption. For those who move swiftly, the future of smart manufacturing promises not just survival but leadership in a new age of industry.

Conclusion

The evolution of smart manufacturing in 2025 marks a defining moment for the global industrial landscape. As technologies like AI, IIoT, digital twins, and advanced cybersecurity converge, manufacturers are reshaping how products are designed, built, and delivered. Embracing these innovations enables businesses to operate with greater precision, sustainability, and agility—qualities essential in an increasingly competitive and interconnected world.

Those who invest early and strategically in smart technologies won’t just optimize performance; they’ll future-proof their operations and position themselves as industry leaders. Ultimately, the smart manufacturing revolution is not only about adopting new tools—it’s about building an intelligent, resilient, and sustainable foundation for the factories of tomorrow.