Key Takeaways

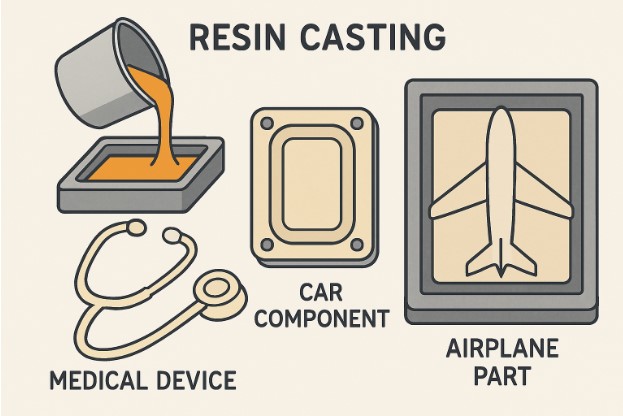

- Resin casting is revolutionizing manufacturing, with applications in the medical, aerospace, and automotive industries.

- Advancements like 3D printing and new resin formulations are enhancing precision, efficiency, and sustainability.

- Understanding these innovations can help manufacturers stay competitive in a rapidly evolving market.

Table of Contents

- Introduction

- Medical Applications

- Aerospace and Automotive Industries

- Integration with 3D Printing

- Sustainable Practices

- Future Trends

- Conclusion

Introduction

Resin casting, once considered a niche process for prototyping, has evolved into a core technology that powers innovation across various industries. Modern techniques enable the creation of complex, durable, and lightweight components, opening up new opportunities for manufacturers and engineers. Whether for rapid development or end-use parts, resin casting facilitates faster production cycles with tailored material properties. The growing versatility of materials, including flexible urethane casting resin essex MA, enables manufacturers to meet demanding industry needs while staying at the cutting edge of today’s market.

This manufacturing process isn’t just about speed; it also delivers unparalleled precision to industries that require high-tolerance parts. With customizable resins and advanced molding techniques, manufacturers can achieve a level of detail and consistency previously unattainable by traditional casting methods. As technological strides continue, the role of resin casting in modern manufacturing is set to expand even further. The integration of specialized resins and casting methods is increasingly supporting sectors such as healthcare, aerospace, and automotive. Resin casting’s adaptability is invaluable, enabling the creation of everything from patient-specific medical devices to lightweight aircraft components. Staying informed about these advancements enables businesses to leverage the latest innovations, resulting in enhanced operational efficiency and improved product quality. As leading manufacturing processes evolve, resin casting stands out as a pillar of progress—both for its adaptability and for the way it incorporates digital design, environmental responsibility, and rapid iteration into mature sectors.

Medical Applications

Precision and patient safety are paramount in the medical field, and resin casting provides solutions that were once deemed impossible. From surgical instruments to prosthetic limbs, customized components are now within reach due to advancements in biocompatible and sterilizable resins. Notably, resin casting enables manufacturers to rapidly develop devices and prototypes, saving valuable time in patient care and reducing costs through shorter production lead times. One breakthrough comes from Cast21, which utilizes innovative resin casts for orthopedic applications. These lightweight, custom-fitted devices provide improved comfort and healing, addressing the old challenges of traditional plaster or fiberglass casts. The adaptability of resin casting further supports the trend toward patient-specific medical devices, which can be customized for better fit, function, and hygiene.

Aerospace and Automotive Industries

Weight reduction, structural integrity, and resistance to harsh environments are key demands in aerospace and automotive manufacturing. Resin casting addresses these needs by enabling the creation of lightweight composite components that do not compromise strength or safety. Advanced resins offer engineers materials that can withstand extreme temperatures and stress, which is essential for components in aircraft, spacecraft, and high-performance vehicles. Additionally, the use of resin casting for prototyping new aerodynamic shapes and functional parts accelerates the product development cycle, allowing manufacturers to test and iterate quickly. Automakers are increasingly turning to resin-cast parts for interior and engine components, where durability, cost-effectiveness, and design flexibility have a significant impact on their performance.

Integration with 3D Printing

The integration between resin casting and 3D printing is a significant game-changer. 3D-printed molds and patterns enable faster and more precise production of intricate parts. This integration democratizes access to complex tooling, making it feasible for smaller manufacturers and startups to bring innovative products to market rapidly. The development of new stereolithography resins, such as the Somos line, enhances yield and accuracy when used in conjunction with 3D-printed molds. These technical advancements enable businesses to quickly transition from digital models to functional products without the prohibitive costs associated with traditional manufacturing. This agility drives competitiveness, particularly in dynamic fields like consumer electronics and medical device manufacturing.

Sustainable Practices

Sustainability is becoming a central focus in modern manufacturing, and resin casting is responding with eco-friendly innovations. Researchers and manufacturers are developing bio-based and recyclable resins that reduce environmental impact without compromising performance. The ability to recycle scrap materials and extend mold life also contributes to waste minimization. This commitment to environmental responsibility is prompting industry leaders to reassess their supply chains and adopt greener practices on a larger scale. As regulatory pressures intensify, sustainable resin casting solutions enable companies to meet compliance requirements and appeal to environmentally conscious consumers.

Future Trends

As we look ahead, the trajectory of resin casting in manufacturing is poised for further disruption. Ongoing research into smart materials, self-healing resins, and advanced automation promises even greater performance and versatility. The continued integration of digital technologies—including artificial intelligence-driven design and data analytics—will further enhance precision, reduce waste, and drive down costs. Manufacturers willing to invest in these advancements can expect to see strengthened supply chains, product differentiation, and new growth opportunities. Those that embrace the full potential of resin casting will remain at the forefront of innovation across industries.

Conclusion

Resin casting has evolved from a specialized technique to a foundational process underpinning modern manufacturing. Through its applications in healthcare, aerospace, automotive, and other industries, it demonstrates unmatched adaptability, presenting opportunities for optimization. As the technology continues to progress, manufacturers that adopt cutting-edge methods and materials—including flexible urethane casting resin—will stay resilient in a changing industrial landscape. Paying close attention to emerging trends, sustainable practices, and technological integrations will ensure long-term success and industry leadership.